Frequently Asked Questions (FAQs)

Table of Contents

- Why print your own thermal labels?

- What do I need to get started?

- What types of thermal labels can I print?

- Can I print in colors?

- What are key factors in selecting a thermal ribbon?

- What determines thermal ribbon price?

- What are key factors in selecting thermal label material?

- What is the difference between thermal transfer and thermal direct printing?

Q. Why print your own thermal labels?

A. Thermal printing allows for printing “on demand”. Some of the benefits include:

- Labels can be customized with variable information – can contain such information as your customer’s P.O., or date of manufacture for example.

- Reduces the inventory levels of labels needed – no need to stock numerous specific labels when they can be printed on demand.

- Reduces waste due to obsolescence – the same labels can be used for each product version – just change the variable information.

Typical applications include:

- Compliant labeling (major retailers, AIAG auto, UPC barcoding, etc.)

- Shipping labels

- Inventory tracking labels with barcodes

- Retail pricing labels – Point of Sale system labeling requirements

- Ingredient labeling – Keep up with the changes in the list of ingredients.

Q. What do I need to get started?

A. Getting started is easy. We can provide all the hardware, software and technical support that you will need whether you need a light-duty desktop printer or a heavy-duty industrial printer. Regardless of the application, the basic components are the same. Here’s what you need:

- A thermal printer

- A PC compatible computer (Windows XP or greater operating system)

- Label creation software

- Cables to connect the printer to the computer

- Labels

- Thermal transfer ribbons

If you are just getting starting and want to purchase a complete package you will be interested in looking at the package deals we've out together.

Q. What types of thermal labels can I print?

A. The lowest cost approach is to use blank white labels in stock sizes. Any size label can be created, however the most affordable is to use stock sizes. Labels are available for both indoor and outdoor applications.

Another option is to use a custom pre-printed a label. Pre-printed labels allow you to have one or more colors on your labels. For example, you could have your company logo and other company information appear on each label printed in a specific color(s).

Using your thermal printer, you would then print any additional information you needed on the labels.

Some applications require tags instead of labels. Tags can be printed just like labels to imprint your logo, pricing and barcode information.

Here are some other printing options available:

- Custom label sizes – any size you need

- Dissolvable labels – for use in kitchens, food service area

- Custom materials – chemical resistant, sunlight resistant, security labels, etc.

Q. Can I print in colors?

A. Yes. Most thermal printers have only one “printing head”. If a color imprint is needed, the black ribbon can be removed and replaced by a color ribbon.

If barcodes are being printed on the labels, a black ribbon (or dark color) should be used to insure that the barcode will be readable.

A limited variety of colored ribbons are available for most thermal printers. We can help you to make sure you have the appropriate ribbon for your label material and application (indoor or outdoor) – if you have any questions, just ask us.

There are a few printers available that can print multiple colors and a black bar code simultaneously. These “process color” printers are more expensive (typically over $10,000 plus training expenses). If you are interested in a “process color” printer, please let us know.

Q. What are the key factors in selecting a thermal ribbon?

A. There are several important factors to consider when selecting a ribbon:

Ribbon width - The ribbon width should extend past the edge of the label material to prevent damage to the print head from abrasion by the label material. For example, a 2.5 wide label would require a 3 inch wide ribbon. Many ribbons are actually larger than their specified width (4 inch ribbons, for example, are typically 4.33 inches wide).

Ribbon type:

- Wax ribbons are the lowest cost and are typically used when long term durability is NOT an issue. They are best for printing on coated or uncoated paper tags and labels. Typical uses are shipping labels, pricing labels, or other indoor applications.

- Wax/Resin ribbons are more expensive, but the imprint is more resistant to scratching and smearing and can resist mild chemicals. They are best for printing on coated paper, coated tags and films such as Kimdura and are suitable for short-term outdoor uses.

- Resin ribbons are the most expensive, but the imprint is very durable and resistant to most chemicals. They are best for printing on synthetics materials such as polyester, polymide, etc.

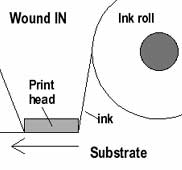

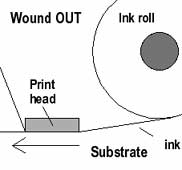

Ink Configuration (IN or OUT):

Specify the brand of printer when you purchase ribbon to assure ribbons are wound in the correct configuration – either ink side wound “in” or ink side wound “out”.

Typical Examples

| IN |

|---|

| Datamax |

| Fargo |

| Sato |

| Avery |

| OUT |

|---|

| Zebra |

| Eltron |

| TEC |

| RJS |

| Intermec |

Roll Core Size:

Confirm the inside core diameter for the brand printer you own

- Typical desktop unit: 0.5 inch ID cores

- Typical table top unit: 1 inch ID cores

Be sure to confirm the ribbon is designed for your printer brand as some cores also have special slots in the core to fit in ribbon feed mechanism.

Roll Length:

Roll length equates to maximum roll diameter. All printers have a maximum roll diameter.

Recommended Ribbons for TEC Printers:

WAX/RESIN ribbons are recommended for the TEC Printers B Series 472, 572, 672 and 872. Using WAX ribbons on these printers is not as effective because the position of the heating element (near the edge as the label comes out of the printer) does not sufficiently bond the wax to the label material.

Sunfast Ribbons:

Imprints exposed to sunlight should be tested for the desired durability. In general, black is very durable to sunlight exposure with minimum fade for at least 6 months. Colored ribbons are more susceptible to fading – some may fade in less than 1 week. However, selected brands and models of RESIN ribbons are sunfast for up to 1 year. If you are using colored ribbons and are concerned about fading caused by sunlight exposure, please let us know so we can help you select the right ribbon.

Q. What determines thermal ribbon price?

A. The price for a ribbon will vary based on the ribbon type, size and color.

Ribbon Type : The type of ribbon used will be determined by your application.

- Wax – Most common, used on uncoated paper labels & tags (lowest cost)

- Wax/Resin – Used on Kimdura, coated paper and coated tags (higher cost)

- Resin – Use on polyester labels and tags for maximum durability (highest cost)

Ribbon Size – ribbon rolls with more square inches of material (width x length), cost proportionally more than ribbons with less square inches of material.

Price discounts are offered for full case quantities of at least 24 ribbons; additional discounts apply to full case orders for 100 or more ribbons.

Color – Black is always the lowest price; colors are more expensive.

Q. What are the key factors in selecting thermal label material?

A. There are several key factors to keep in mind when selecting label material:

Core Size: Typical core inside diameter sizes are 1 inch, 1.5 inch and 3 inch. Size is determined by the brand and model of printer you own.

Wound In or Wound Out:

Label orientation is either wound with labels facing IN or facing OUT

Finished roll diameter or fan-folded packs:

Most desktop style printers use rolls on a 1 inch ID core and a maximum 5 inch OD roll. Most standard printers use rolls on a 3 inch ID core with a maximum 8 inch outside diameter. For Allegro Style printers, the maximum is 6 inch OD. To use larger diameter rolls (up to 16 inch OD), purchase an optional UNWINDER.

Another option are labels in fan-folded packs, which fit most printers.

Material Type:

Labels are designed to be receptive to thermal transfer printing. Material choices and typical applications are:

- Paper labels – shipping, price tags, inventory tags, and other indoor applications

- Polypropylene – ingredient labels, etc

- Paper tags – equipment labels

- Synthetic Tags (Vinyl, Kimdura, etc) – landscaping, lumber, and other outdoor applications

- Polyester labels – asset tags, product labels

LABELS WITH MAXIMUM DURABILITY

Applications that require maximum durability for barcode labels (barcode labels for rental skis, outdoor assets tags, labels exposed to harsh chemicals, etc), should be laminated with a clear film. To produce laminated labels on demand requires additional capital equipment (about $30,000). We can provide this type of equipment, however most customers find it more economical to have Thermal Images produce this product.

(click here for additional information on laminated labels)

Q. What is the difference between thermal transfer and thermal direct printing?

A. The main difference is direct thermal printing does not use a ribbon. Direct thermal printing does require the use of special heat sensitive substrate material. The printer head activates the heat sensitive coating on this material forming a black image.

Thermal transfer printing uses a ribbon from which ink is transferred under heat and pressure to the substrate. The color and other characteristics of the imprint can be changed by changing ribbons.